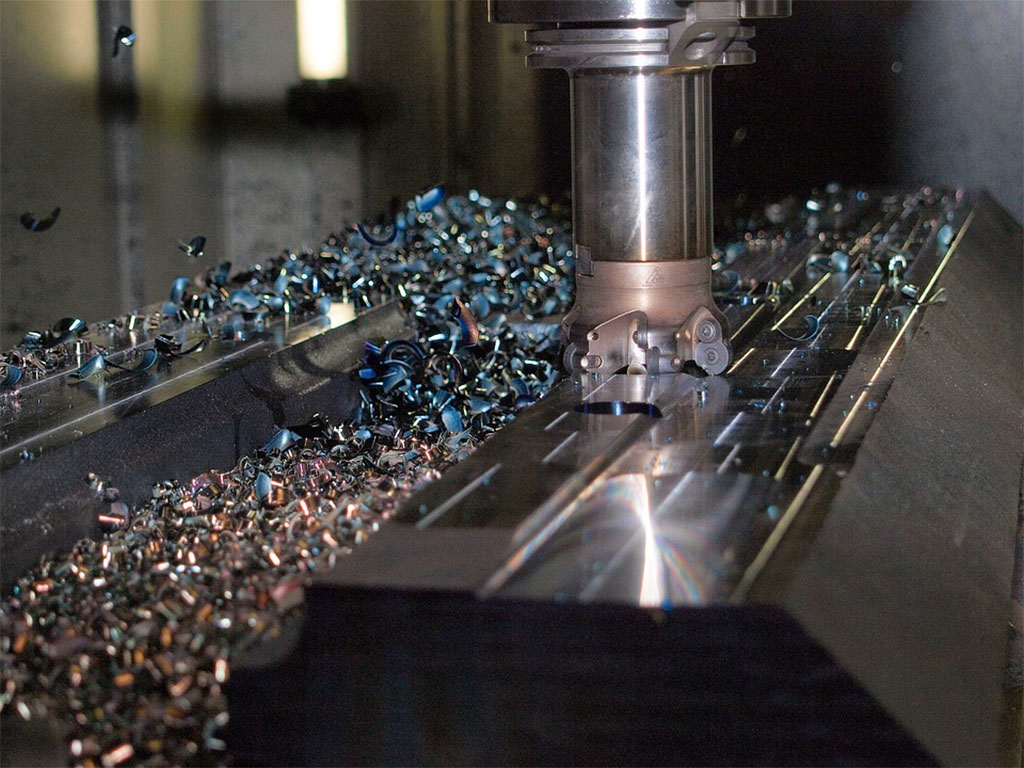

Such machines are indispensable for providing your services or products. Do you have a custom metal part that needs to be adapted or produced for a machine? Since 1957, Vanderscheuren nv has been an all-in supplier of semi-finished products or fully-assembled end products for machine builders. SMEs and large companies in Belgium, the Netherlands, Luxembourg and Northern France rely on our expertise in terms of CNC turning, CNC milling, sheet metalworking, manual welding, robotic welding, assembly and surface treatments of various types of metal. We also produce custom hydraulic cylinders to move machines or parts.

Types of metalwork we can do

Have your metal parts machined to order using any of the following techniques:

- diameters ranging from 4 mm to 800 mm

- lengths of up to 1,400 mm

- lengths ranging from 10 mm to 6,000 mm

- widths ranging from 10 mm to 800 mm

- heights ranging from 5 mm to 600 mm

- lengths of up to 4,900 mm

- widths of up to 800 mm

- heights of up to 700 mm

- surfaces of 3,000 mm by 1,500 mm

- sheet thickness of up to 20 mm

- surfaces of 6000 mm by 1,500 mm

- sheet thickness of up to 300 mm

- lengths of up to 4 m

All dimensions are possible for the following:

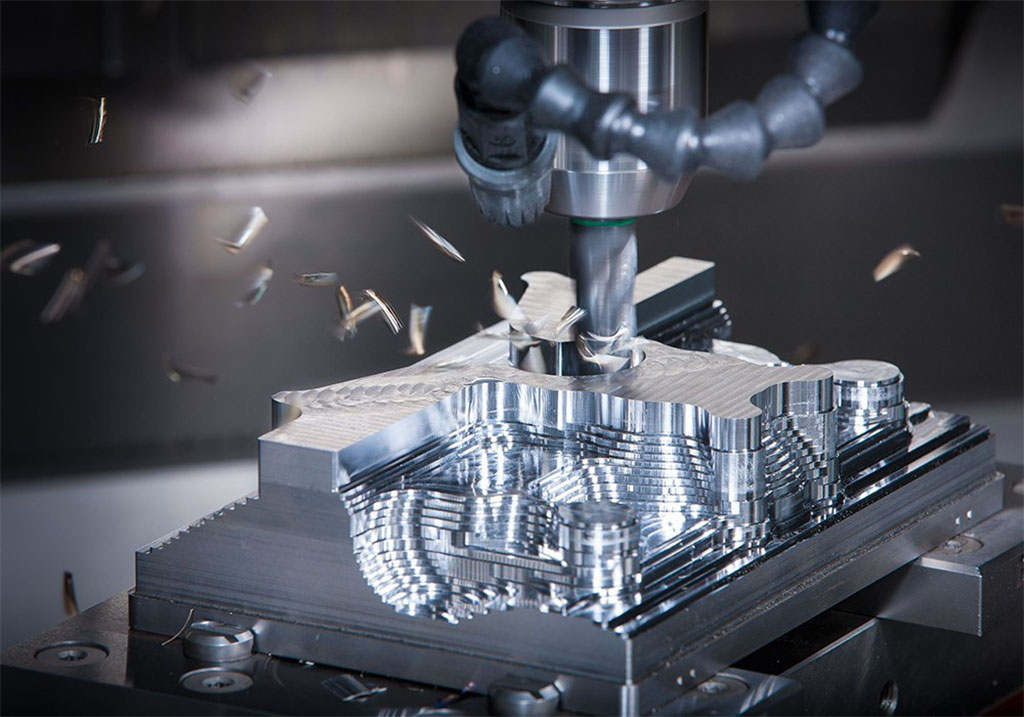

Do you need complex custom metal parts?

Product or machine building often require customisation. Thanks to our high-technological machines and the expertise of our employees at Vanderscheuren nv, we are able to process the most complex custom metal parts.

Our engineers base themselves on the design that you supply to us or have developed by us. From the design stage onwards, we start thinking about we can produce the part for your machine in a feasible, practical and affordable way. We determine the most suitable metal for your application and process it into the required end product, according to the right techniques.

1. Draft of the quotation and discussion

As soon as we have received your request, we review all the information and draw up a price quote. We then meet with you to discuss your concept and your expectations, the technical information, the quality and the desired delivery term. We incorporate this information in our quotation.

2. Technical design

At Vanderscheuren nv we work to a technical drawing, a 2D or 3D design. Either you supply this to us or our engineers create this for you.

3. Dispatch of the quotation and registration

As soon as the technical drawing is complete, we finalise your price quotation and send it to you. When we have received your approval or order, we register it in our price quotation system.

4. Internal meeting

All our department heads meet to map out the possibilities, bottlenecks and price indications of your concept.

5. Production

We launch the first production run of your part. After a first piece inspection, we make adjustments and produce your project.

6. Delivery and invoicing

You will receive the final product within the agreed deadline. We will send the invoice when the entire process has been finalised.

Your point of contact for custom metal parts

Vanderscheuren nv has been producing custom metal parts for SMEs and large companies in Belgium, the Netherlands, Luxembourg and Northern France since 1957. Thanks to our high-quality machines, we are able to process several types of metal: We supply semi-finished products as well as fully-assembled products, as piecework and in series.

We aim to maintain long-lasting relationships with our customers by rigorously checking the quality of our work. We have a dedicated quality control and customer service department, a climate-controlled measurement chamber and a fully-equipped workshop with machinery for this. Our expert team takes every aspect of the metalworking process off your hands, from the engineering to the delivery of your product(s).

More innovation, productivity and turnover

Increasing innovation, productivity and turnover is a top priority for many companies in the machine engineering industry. It’s one way of strengthening your competitive position, in addition to creating added value for your customers. You can modernise your machines by having metal parts or entire machines custom-built. Moreover, they can also handle larger capacities, last longer and become more user-friendly and ultimately also increase your turnover.

Types of metal for machine engineering

Rustproof or stainless steel

Rustproof steel contains chromium, carbon, nickel and iron, among others. It is an easily machinable type of metal for machine applications that often come into contact with water. Rustproof steel is water-resistant, as well as corrosion-resistant, making it ideally suited for the production of custom metal parts.

Aluminium

Do you need lightweight metal parts? Aluminium is an interesting option in that case. This material has a natural, protective oxide layer, making it resistant to corrosion and the outside air. Aluminium has a low melting point and is easy to machine.

Steel

Steel is a strong, lightweight material! It can take a beating, but is also very malleable. This combination means steel has a very long life. Do you need custom metal parts for an interior application? Steel is definitely a good choice.