Do you need a custom metal part to develop a machine or product? Vanderscheuren nv can process whatever you need, be it a complicated prototype or serial production of a part. Thanks to our high-technology machines, we can CNC mill, CNC turn, process, assemble, manually weld and robot weld all kinds of metal. Does your metal part then need a surface treatment? We will gladly take care of this for you too.

Maximum dimensions for milling at Vanderscheuren nv

The dimensions that we mill by means of CNC milling:

- lengths ranging from 10 mm to 6,000 mm

- widths ranging from 10 mm to 800 mm

- heights ranging from 5 mm to 600 mm

The advantages of CNC milling

CNC milling provides major advantages:

- short production and delivery times

- extreme precision

- consistent and flawless product quality

- simple and more complicated products

- serial production and prototypes

- various types of metal (steel, galvanised steel, Corten steel, aluminium, Hardox®, stainless steel and PVC)

- short production and delivery times

- extreme precision

- consistent and flawless product quality

- simple and more complicated products

- serial production and prototypes

- various types of metal (steel, galvanised steel, Corten steel, aluminium, Hardox®, stainless steel and PVC)

CNC milling in all kinds of industries

CNC milling provides numerous advantages for all kinds of applications in a wide range of industries:

Vanderscheuren nv, amazing precision work

Vanderscheuren nv is a reputable metalworking company, based in West Flanders (Belgium), that has been providing custom all-inclusive solutions for over 65 years in all of the Low Countries and Northern France. We have built up long-lasting customer relationships with machine builders and project developers in a wide range of industries and always look forward to a new challenge. We hold ISO 9001 certification and have a dedicated quality control department, a customer service department and sophisticated machinery. We have everything it takes to produce your product in a feasible, practical and affordable way.

What is CNC milling?

CNC is the abbreviation of “Computer Numerical Control”. CNC machines are computer-controlled and are used for the automated processing of materials and semi-finished products. The machines are programmed, which means that they can endlessly repeat the most complex processes with micro precision, both in series and as piecework.

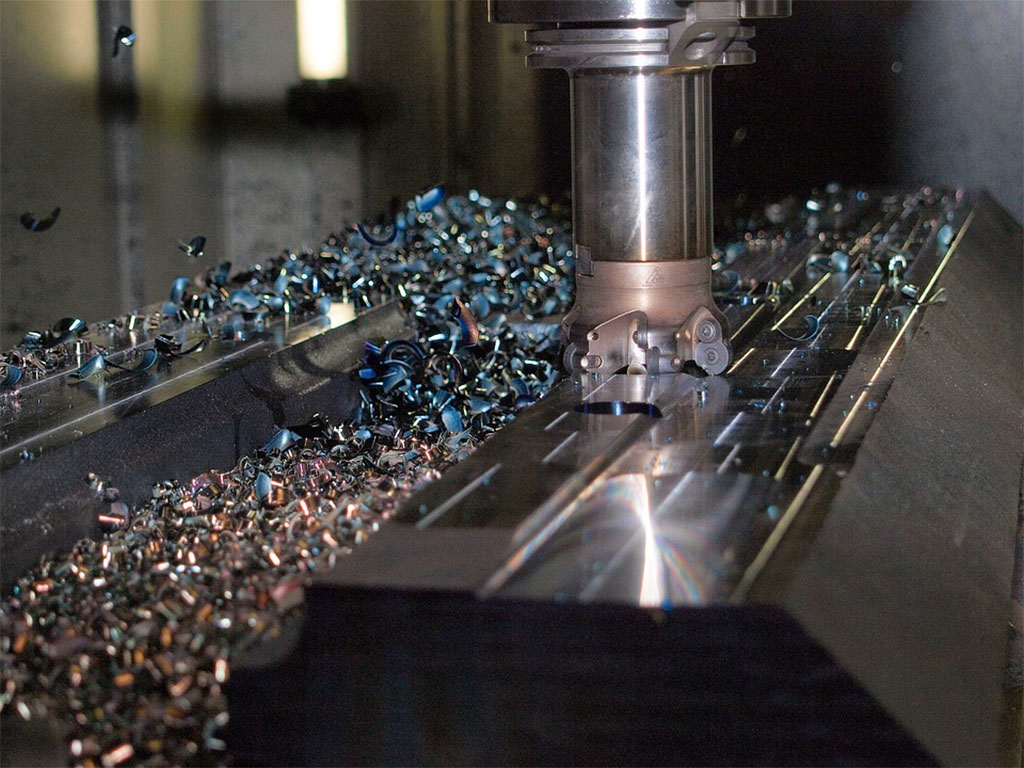

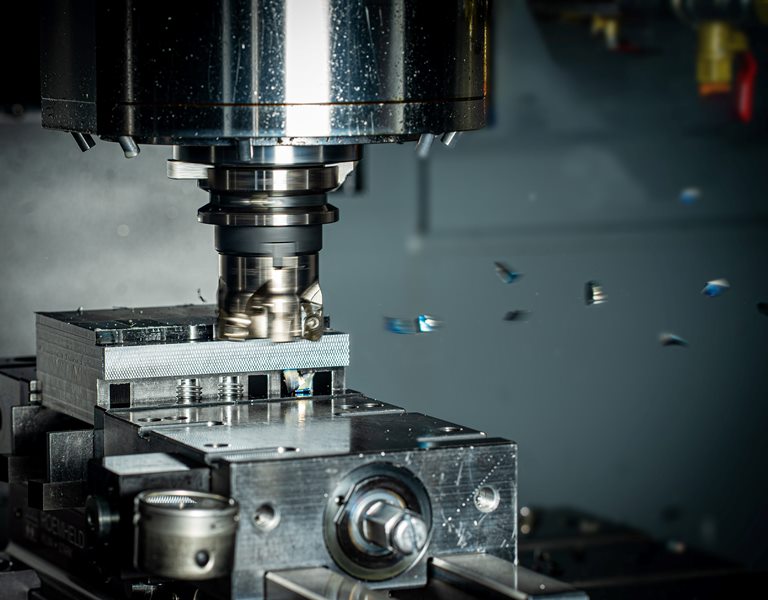

CNC machines can be used for various machining processes, such as CNC turning and CNC milling. A CNC milling centre contains a cylindrical milling tool that rotates at high speed. The metal to be machined disappears as soon as it comes into contact with the sharp teeth of the machine headstock. By moving the headstock over the material, the machine creates an extremely smooth surface that meets high tolerance requirements. By so doing, we can process the metal from different axes and create various shapes, holes or slots. The main difference from CNC turning is that, in milling, the tool itself moves and rotates while the product remains stationary.

Automated CNC milling by using CAD/CAM software

The CNC milling centre relies on digital drawings to perform specific processes. We use CAD/CAM software for this. You provide us with 2D or 3D drawings or our technical draughtsmen create a digital design for you. We upload this drawing (the CAD design) to our CAM software which generates the machine code for the CNC milling centre. The machine relies on the machine code to know which operations it must perform at which turning and milling speed, what the product’s position in relation to the headstock is and which milling tools are required. The headstock has a tool change system and can perform multiple types of milling operations during one session.

Some CNC milling options

1. 3-axis CNC milling

In 3-axis machining, only the top side of the product is machined. The headstock moves perpendicular along the X‑, Y and Z axes.

2. 4-axis CNC milling

In 4-axis machining, the headstock machines the product along four axes of movement. The additional rotating axis can rotate the workpiece.

3. 5-axis CNC milling

In 5-axis machining the product is machined on five sides in one set-up. The fifth axis (the B-axis) rotates the spindle from left to right.

4. Vertical CNC milling

Vertical milling centres have a vertical spindle and do not take up much space. Due to their relatively small base, less floor space is required and the processing area is easily accessible to the operator.

5. Horizontal CNC milling

In horizontal milling centres, the spindle is in a horizontal position, which is excellent for the precision machining of large series.

6. CNC turning and CNC milling

The CNC turning and milling centre is ideally suited for parts that need both milling and turning. It combines CNC turning and CNC milling.

7. Bevels

CNC milling is used to create bevels on parts of welded constructions. Thanks to the bevelled welded edge, parts can be welded together much more easily.

8. Face milling

Metalworking is subject to tolerances. There may be a deviation between the product and the nominal size, for example. Did previous machining of the metal influence this tolerance? We use face milling to eliminate any such deviation.