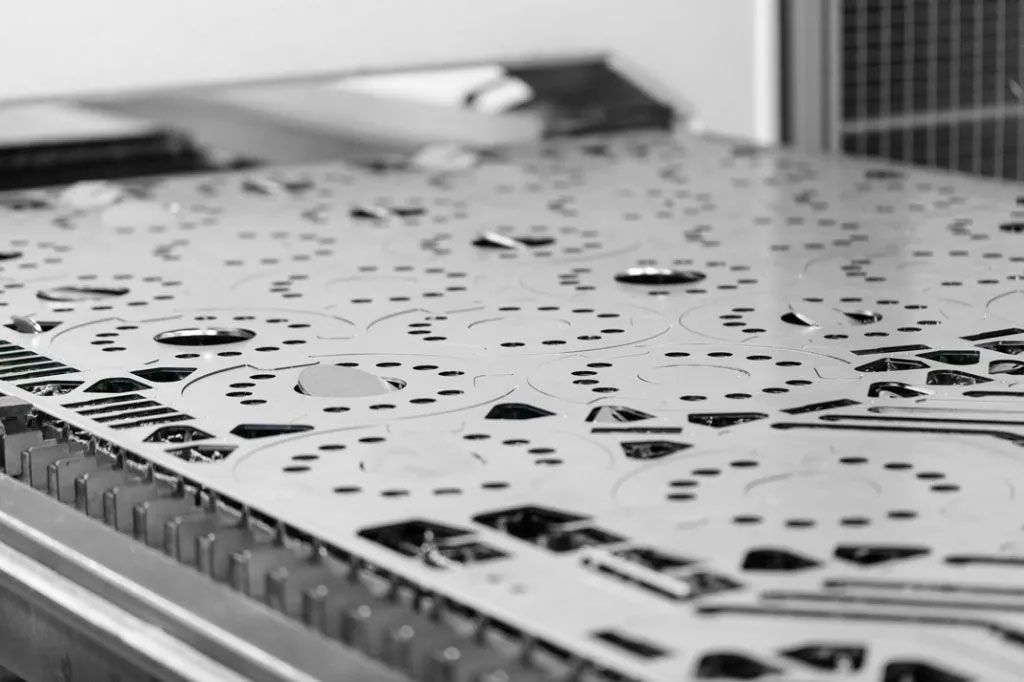

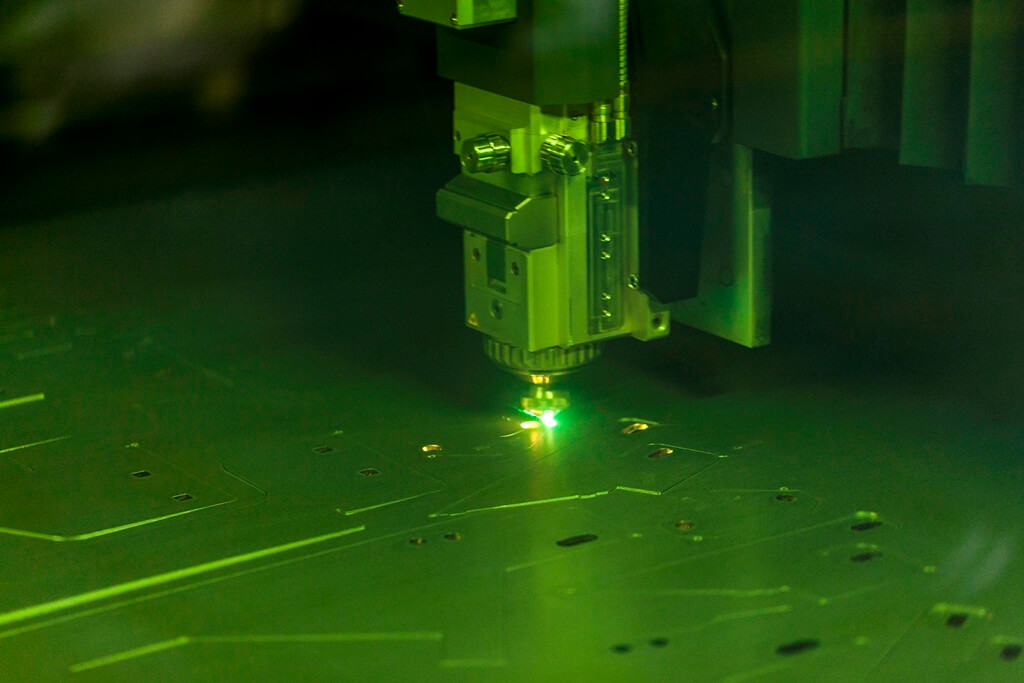

Do you need a semi-finished product or completely finished product in metal? At Vanderscheuren nv we unburden SMEs and large companies in a wide range of industries by providing them with custom metalworking solutions. We operate in Belgium, the Netherlands, Luxembourg and Northern France. We use our high-technology machines to produce compact as well as very complex designs, in series or as piecework. We can provide all kinds of services, including sheet metalworking, CNC turning, CNC milling, manual welding, robotic welding, assembly and surface treatments for all types of metal. Finally, we also produce custom hydraulic cylinders. Discover the numerous options and benefits of laser cutting, bending and autogenous welding.

Request your price quotation today and we will provide you with just-in-time delivery