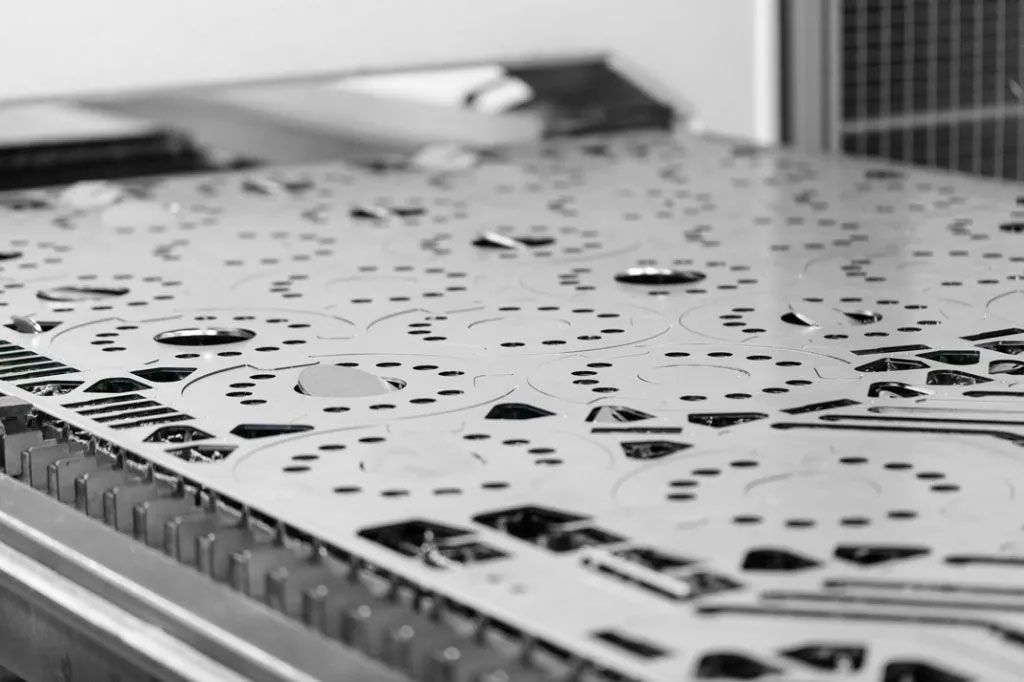

Metalworking is useful in a wide range of applications in the food industry, such as appliances, installations or machines. In most cases this is stainless steel, but solutions in aluminium, carbon steel and copper are also possible. At Vanderscheuren nv we have handled metalworking jobs for SMEs and large companies in the food industry for over 65 years. These can include semi-finished metal products as well as fully-assembled and tested end products, as piecework or in series. Is your company located in Belgium, the Netherlands, Luxembourg or Northern France?

Contact us for a price quotation and a custom solution with no strings attached